Engine Build Specifications

3ltr (2994cc) Displacement Nissan L-Series

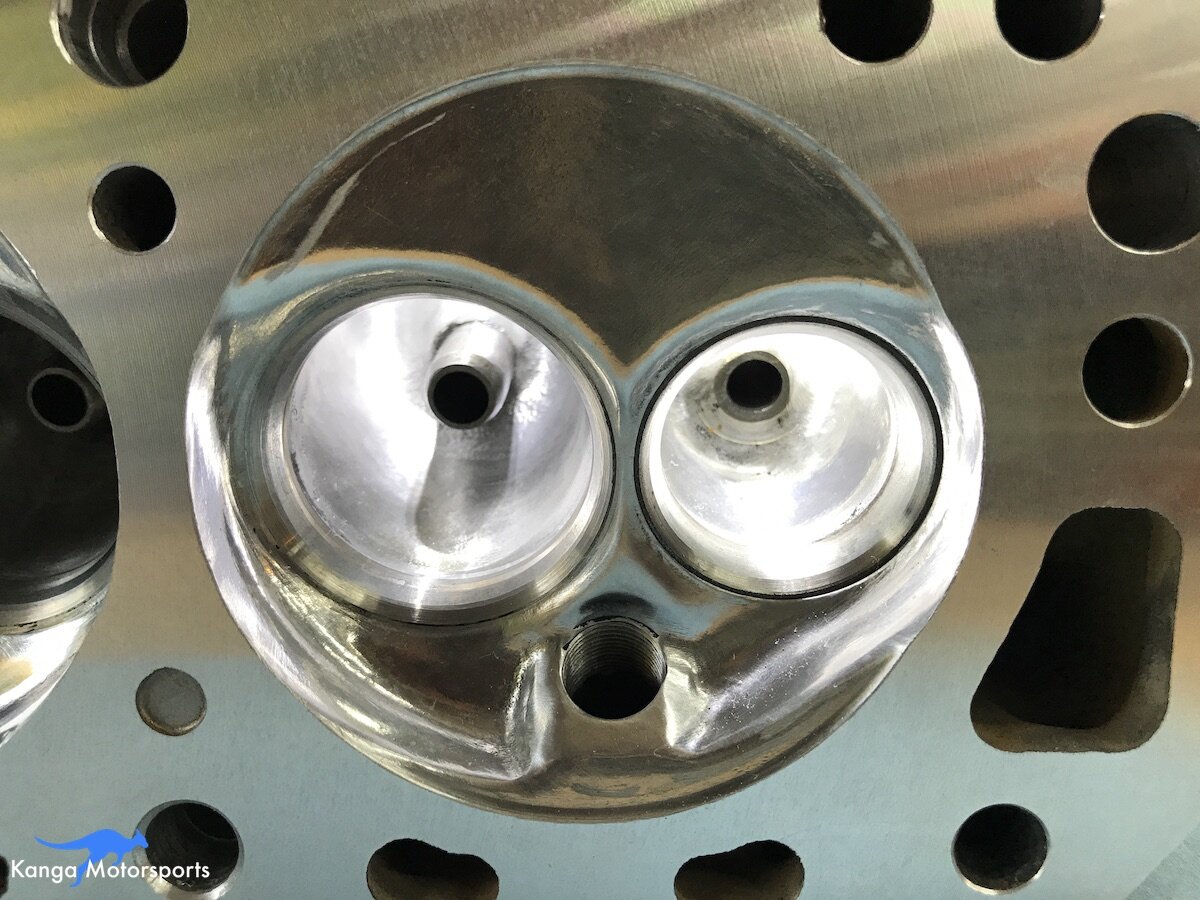

Custom Port and Polished Nissan N42 Head

Supertech Undercut Stem Intake Valves

Nissan OEM Exhaust Valvles

Rebello Racing Outer Valve Springs

Rebello Racing 279-.540 63DI 109 Hot B Camshaft

Rebello Billet Spray Bar

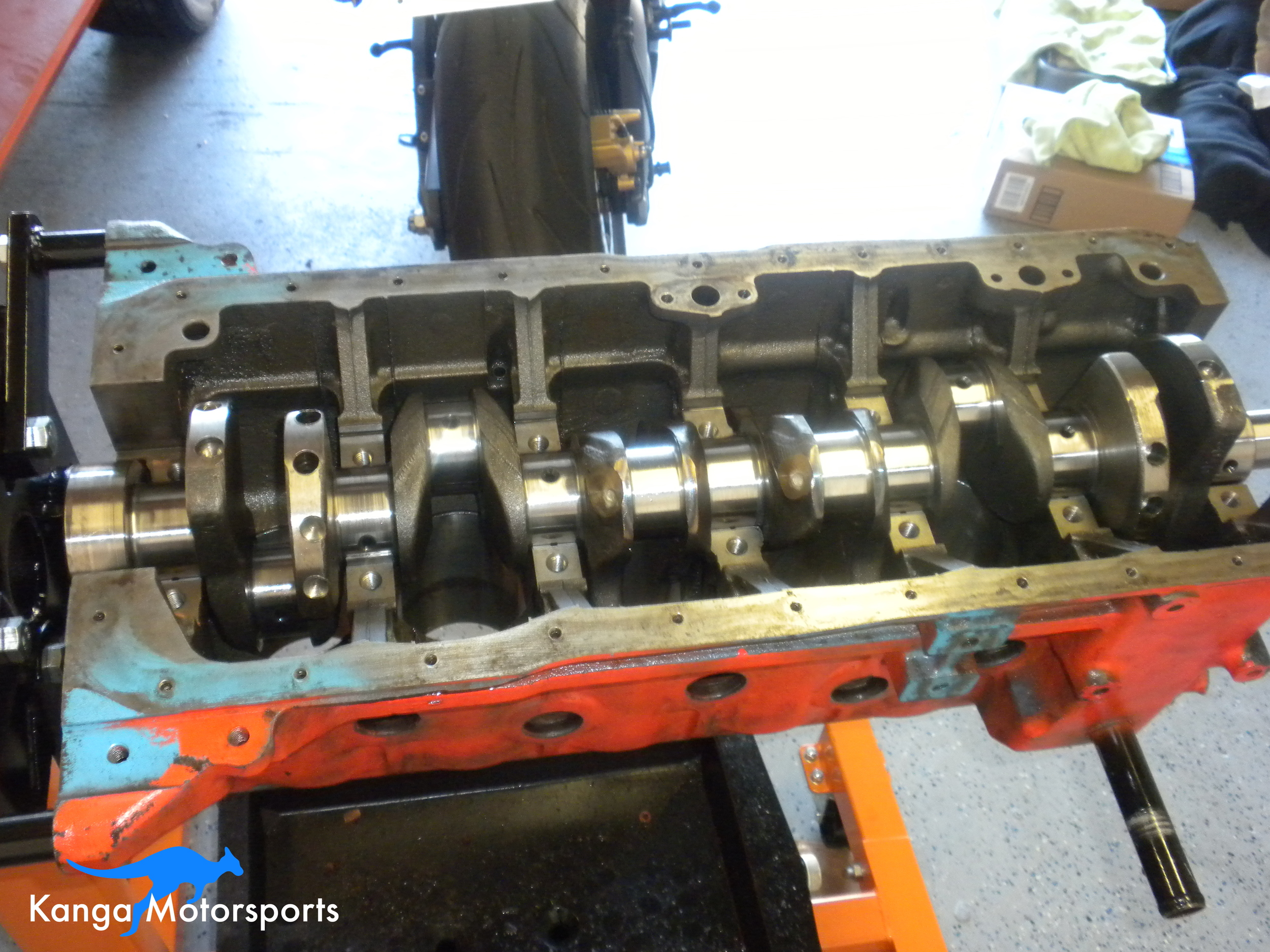

Custom Modified Nissan F54 Block

88.5mm JE Forged Pistons

Plasma Moly Rings

Forged H-Beam Eagle Rods

Clevitte Tri-Metal Main Bearings

King Racing XP Coated Rod Bearings

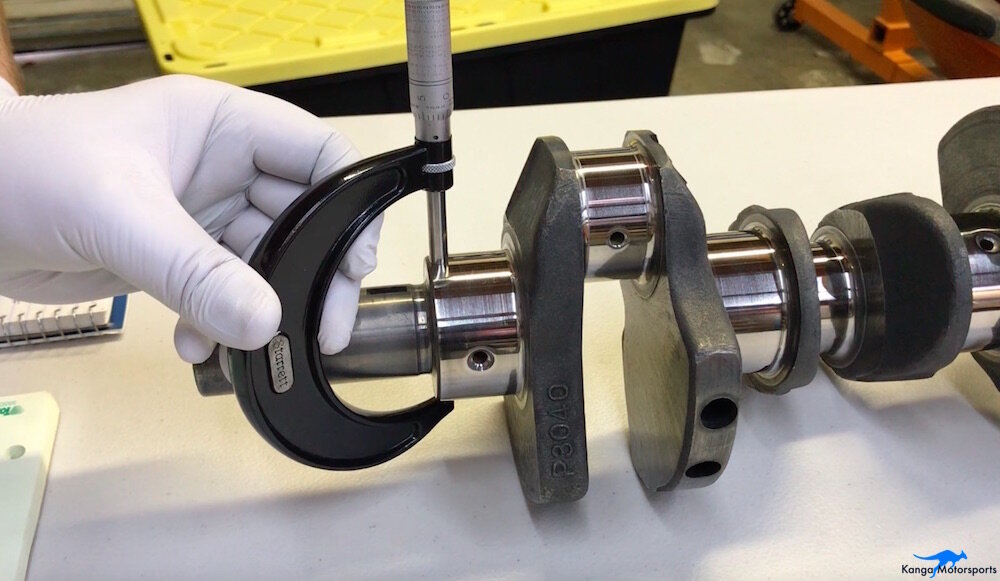

Stroked and Nitrided L28 P3040 Nissan Crankshaft

Cometic MLS Head Gasket

Rebello-BHJ Competition Dampener

Ported Nissan E88 Intake

Hitachi SU Carburetors with ZTherapy Nozzles and Needles

Nissan High Flow Turbo Oil Pump

Arizona Z Car Cast Aluminum Oil Pan

Datsun-Zstory Stainless Steel Race Header, Main Pipes and Street Muffler

Engine Build Articles

Before you assemble the engine components make sure all the threads are in good condition and clean. You really don’t want old rust and grime getting into your fresh motor.

We strip, clean and prepare the oil pan for the Datsun Engine Build. We also check and ensure smooth operation of the oil trap doors and baffles.

There are a lot of great resources out there on Engine Building here are some ones we found useful and also specific books and links for the Nissan / Datsun L-Series motors.

With all the modifications and upgrades complete on the engine block it was time to get rid of that horrible looking outer surface and give it a fresh coat of paint.

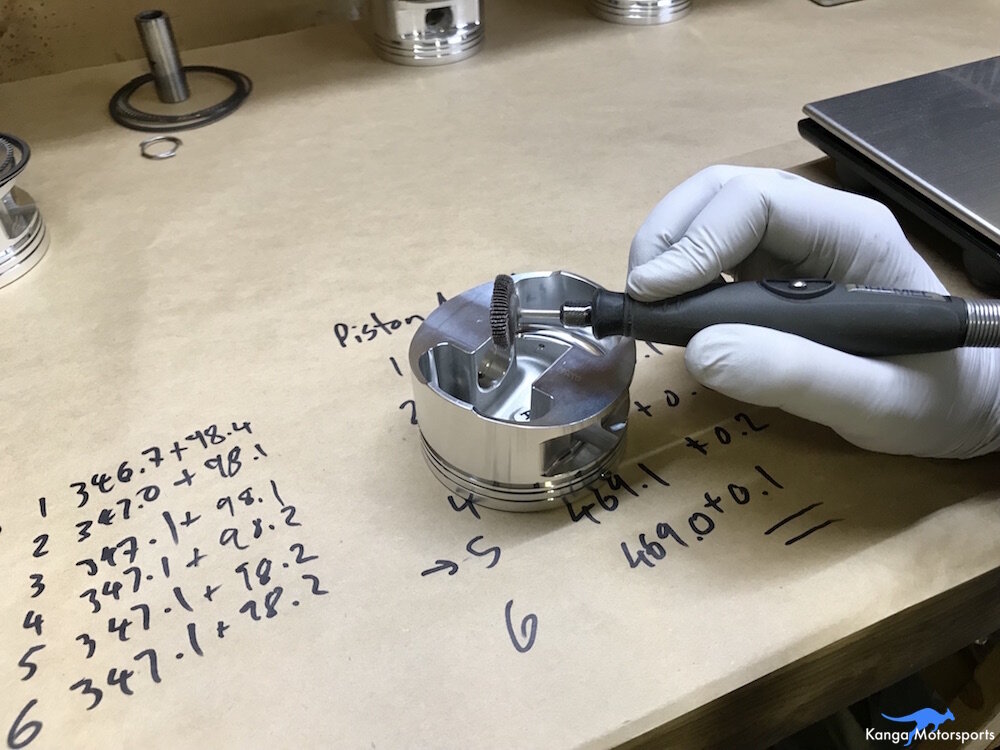

Using a scale you can mix and match the various piston assembly parts (piston, rings, gudgeon pins and retaining snap rings) to get the weight balance close and then modify the pistons by removing material to fine tune.

The next step in our Datsun Engine build series is to set the piston ring gaps. Gapping the piston rings is important to the performance and reliability of the engine.

We unbox the mighty Robello Racing 3.0L Kit for the Datsun L-Series engines. We discuss the various components, specifications we choose and the work ahead to turn our new motor into a beast.

The next step in our Datsun Engine build series is to clean out all the old rust, grinding dust, grease, oil and grime that has built up from the previous work.

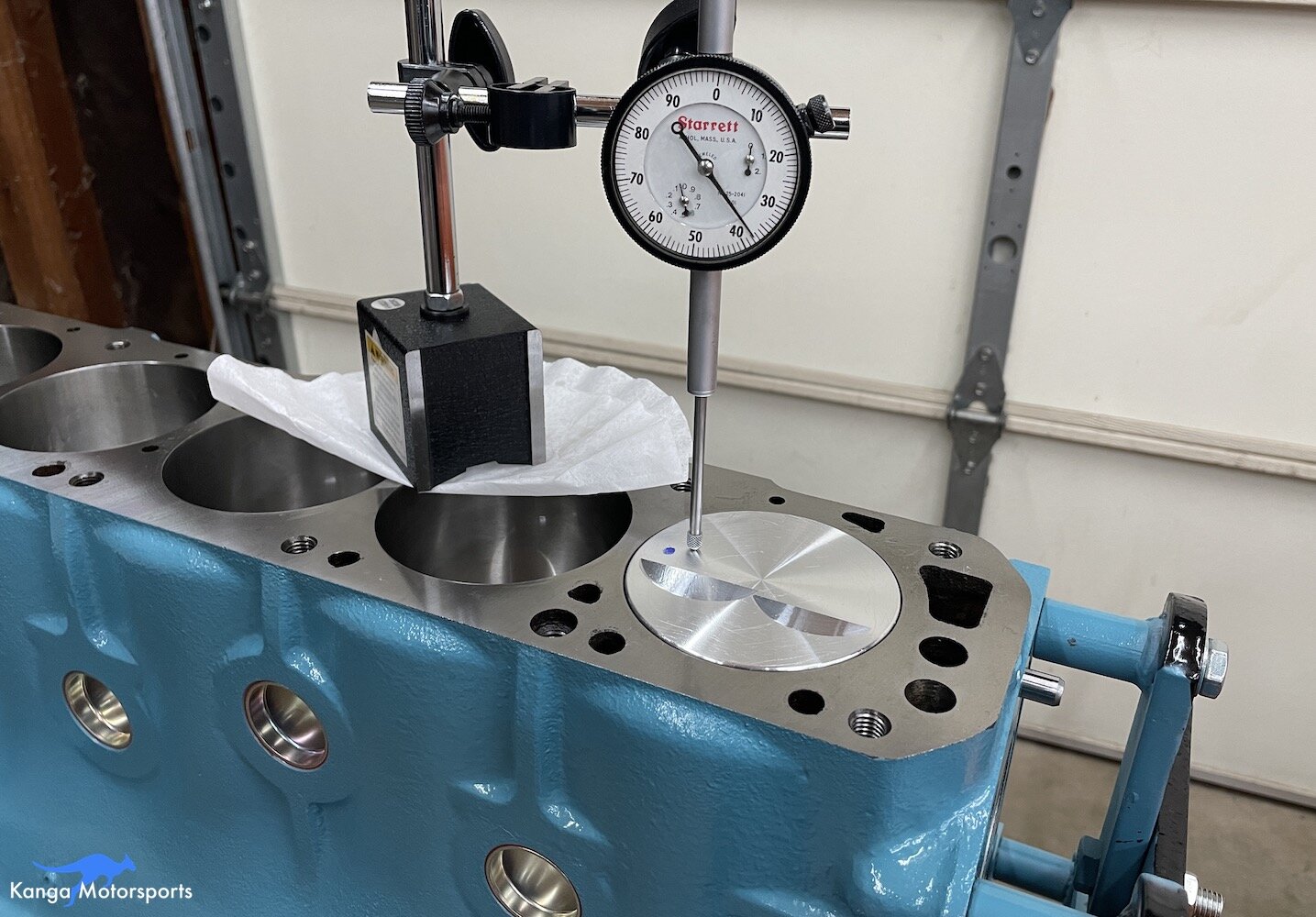

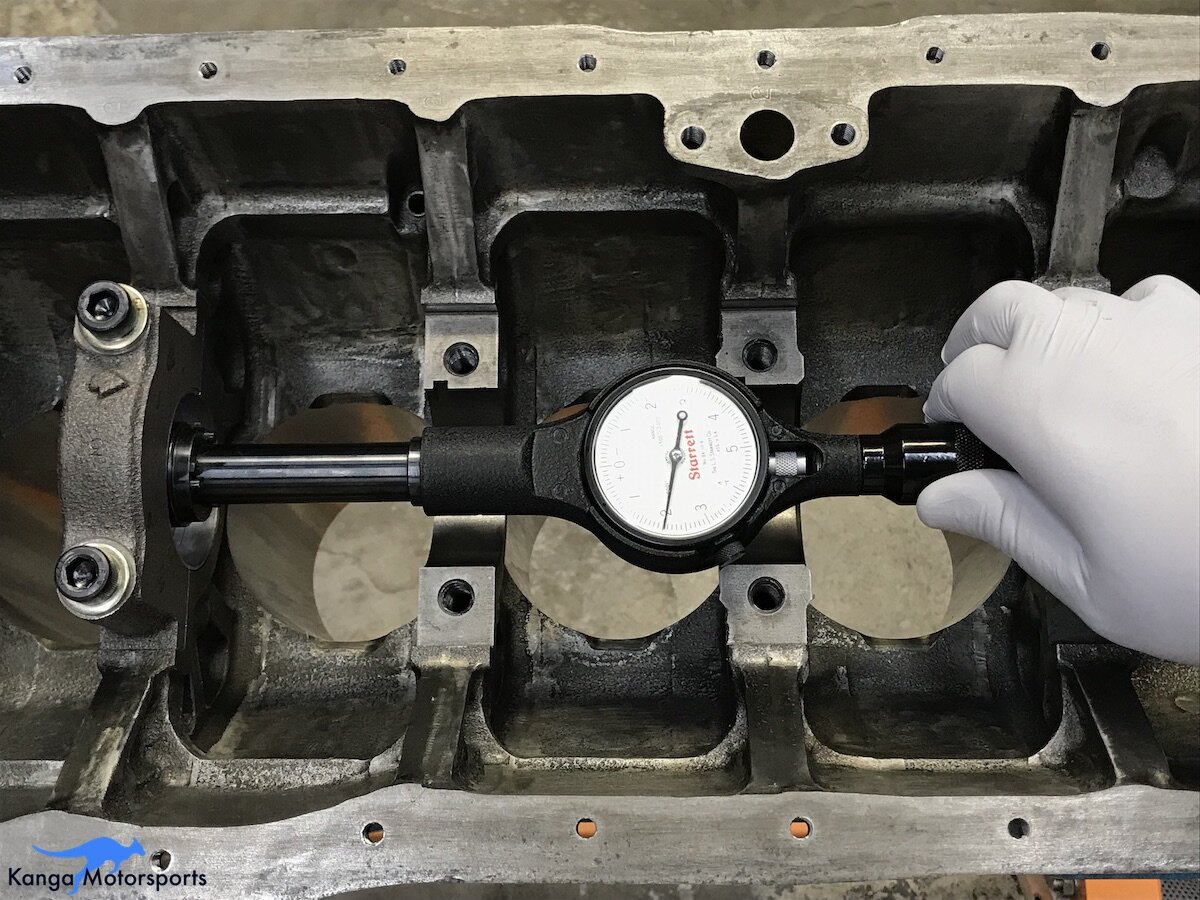

We had a few upgrades done at the machine shop to add some performance, serviceability and reliability to the Datsun L28 F54 Engine Block.

With the block back from the machine shop it is time to clean off all the old rust and paint.

Before taking the engine block to the machine shop you can clean up the interior block surface and remove any casting flash.

Before you can start modifying the engine block you need to know what you have. During the disassembly process measure the engine parts and compare them to the Nissan specifications.

Intakes are typically cast and consequently can end up with casting flash and misshapen ports due to mold shifts. If you are porting your cylinder head you already have all the supplies you need to also port your intake.

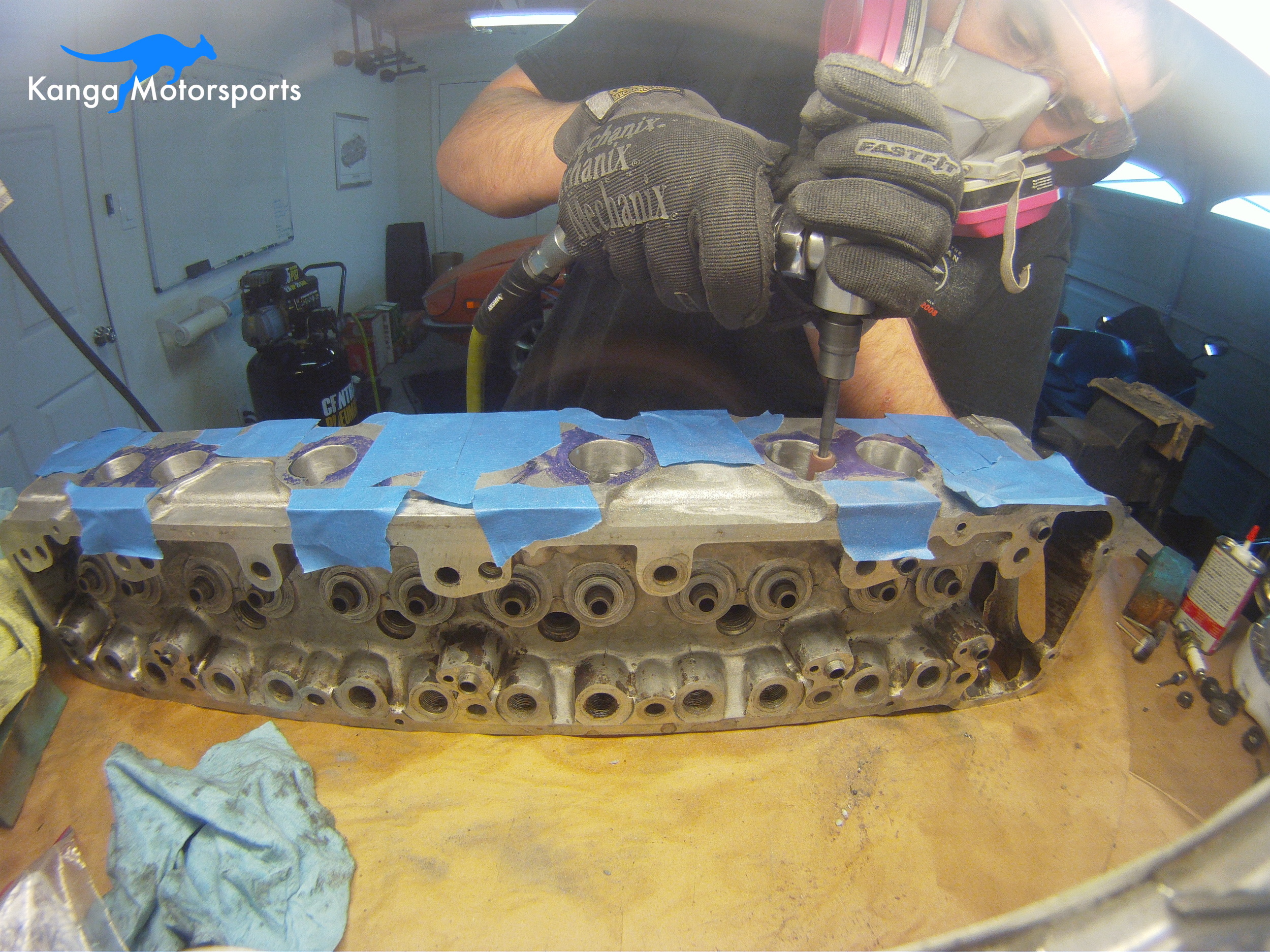

One big area for improvement on the L-series heads is modifying the intake and exhausts ports. Here is a step-by-step guide for porting and polishing the ports.

Key to increasing the performance of an L-Series motor are modifications to the cylinder chambers. This article covers CC'ing, unshrouding the valves, valve set transitions and chamber polishing.

With the Datsun Cylinder Head disassembled now is the time to clean it and see what you have before you begin making performance modifications.

Disassembling a Datsun Cylinder Head is straight forward with a few unique tools. Once the head is dissembled and cleaned you can begin making performance modifications.

The engine in my Datsun 240z at the last track day started to feel underpowered and then began smoking on take offs. Time to investigate...