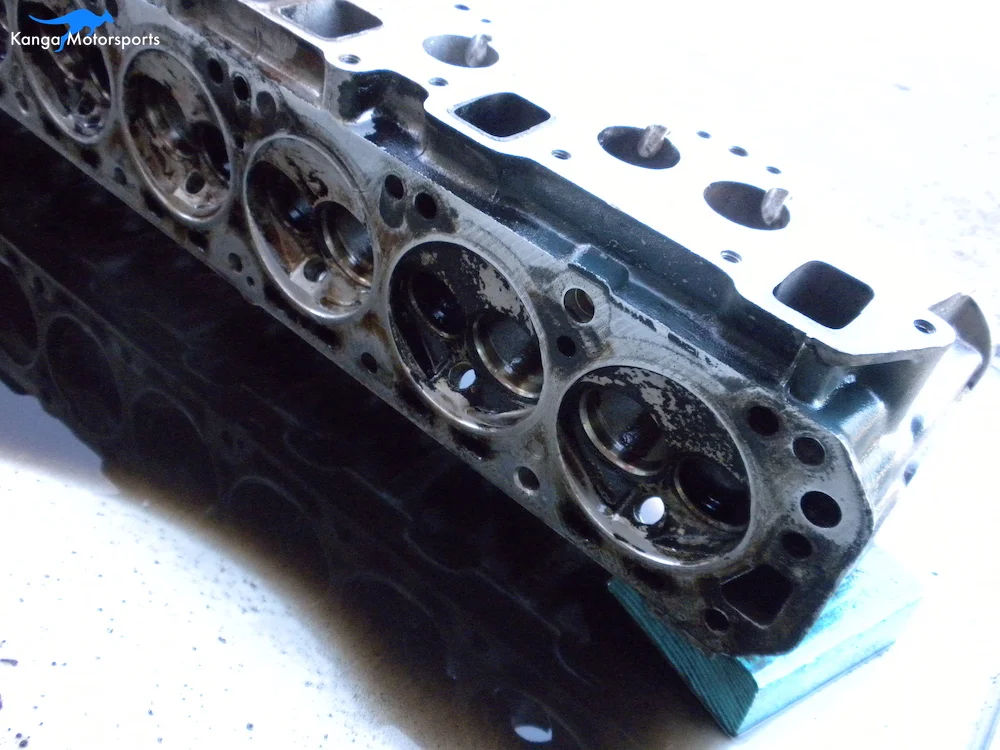

In the previous article we disassembled the N42 Datsun cylinder head. Before you can start making performance modifications you need to clean the cylinder to see what you have to work with. Depending on the condition of the cylinder head it might be incased in dirt, grease, oil and carbon build up.

Tools and Equipment Needed:

- Air Compressor

- Siphon Gun

- Low Vapor Mineral Spirits

- Metal Drip Tray

- Safety Glasses

- Gloves

- Respirator Mask

- Stiff bristle plastic brushes (Harbor Freight PN: 93610)

- Old Toothbrush

- Pipe Cleaners

- Carb Cleaner

- HD Pro Simple Green

- Paper Towels

- Gasket Scraper (TEKTON 5876)

- Razor Blades

- 24 inch Straight Edge

- Fine Feeler Gauges

- Large Metal Drip Tray

- Large Tub

- Hot Water

- Dremel with Flex Shaft

- Brass Bristle Wheel (Dremel PN: 535)

- Carbon Steel Wheel (Dremel PN: 428)

Cleaning the Cylinder Head

The cylinder head should now be disassembled. Depending on the condition of the cylinder head it might be covered in dirt, grease, oil and carbon build up. The hardest thing to remove is the carbon build up.

Start by removing as much of the gunk (dirt, grease and oil) build up using paper towels and simple green. Once you have the majority off it should be easier to see what you have to work with. Gasket pieces might be stuck to the head you can use a gasket scraper to remove these pieces. Be very careful not to scratch or gouge the gasket surfaces.

Likely you will have lots of carbon deposits left and some other hard to get off grease and oil.

If you have a large tub you can fill it with hot soapy water using the HD Pro Simply Green. Submerge the head and use the stiff plastic bristle brushes and pipe cleaners to work the deposits and remove as much as possible.

Normal Simple Green can eat away at aluminum using the HD Pro Simple Green should be safer for aluminum, it is the same formula used in aviation for aircraft cleaning. Either way I would avoid leaving the head soaking for a long time.

The scrubbing should remove most of the remaining dirt, oil and grease. Some of the carbon deposits may remain and there might still be residues. You can use the Dremel and a brass brush wheel combined with some simple green to remove grime in the head passages and spark plug threads.

To clean the head gasket and other gasket surfaces use a razor blade and keeping it completely vertical using light pressure with a gliding motion. Be very careful not to scratch or gouge the surfaces. Don't use the razor blade at non vertical angles as the hard steel blade can dig into the softer aluminum head. You are not trying to remove cylinder head material with the razor blade just the contaminate build up and any hard to remove gasket pieces remaining. Blow any dust away with clean dry filtered compressed air.

Place the cylinder head on the metal drip tray, use as large a tray as possible to catch all the dirt. Oil drip pans with edges work well. Use safety goggles and a respirator mask. Connect the air compressor to the siphon gun and feed it with mineral spirits. This creates a high pressure mineral spirits parts washer. You will be amazed at how much dirt it will clean off.

Next use clean compressed dry air with an inline filter to blow dry the entire cylinder head and passages.

The cylinder head should be mostly clean at this point. There might still be some carbon build up in the combustion chambers. You can use the Dremel and a brass brush wheel combined with some simple green to remove the stubborn carbon deposits. Don't press hard using the brass brushes, you are not trying to scratch or remove material from the surfaces just the carbon deposits. You can also us the brass brush to clean out the threads including those of the head plugs and rocker pivot locations.

With the cylinder head now clean it is a good time to measure the flatness of the cylinder head surface. You want to measure at multiple locations, use a note pad and pen to record your measurements as you go. Lay the straight edge across the cylinder head lengthwise. You want to place it at the front, middle and back of the head. Then do the diagonals from each corner to the opposing corner, do both diagonals. For each placement of the straight edge use the fine feeler gauges and attempt to slide them between the straight edge and the head surface. Try different size feeler gauges and determine the locations and height of any flatness variations. Make these locations and heights in your note pad.

The standard Nissan specification for flatness is 0.05mm (0.0020 inches) and the maximum is 0.1mm (0.0039 inches). Likely you will find the worst areas will be pockets between the central combustion chambers. You might need to deck the head when you take it to the machine shop. There is only so much material you can shave from the head to make it flat. Speak with your machinist.

The cylinder head will need to be cleaned after all the grinding, sanding and polishing involved with porting. Submerge the head in hot soapy water again and rinse out all the ports, passages and threads. Use hard plastic bristle brushes and pipe cleaners to help remove build up and make sure all debris are removed. You might need to do this several times. You can repeat using the high pressure siphon gun and mineral spirits to do the final cleaning. Follow using clean compressed dry air with inline filter to blow dry the entire cylinder head and passages.

In the next article in the engine build series we begin the performance upgrades to the cylinder head by modifying the combustion chambers.