An engine compression test is a quick way to check if a motor is healthy. It examines whether the piston rings, valves and head gasket are all sealing properly. It is a useful diagnosis tool for an engine after an overheat or if you suspect your engine is worn and down on power. When loosing the alternator belt on the Spec Racer Ford Gen3 you can quickly overheat then engine, Without the belt the water pump stops turning cutting water flow and cooling. If this occurs shut the engine off quickly and safely park out of the way. A compression test is one of the simplest diagnostics that can be performed to check that you haven't damaged the motor.

Parts and Tools Needed

Compression Test Gauge

Spark Plug Socket

3/8th drive ratchet and extension

Magnetic pick up tool

Old piece of AN6 or 3/8th inch hose

New Spark Plugs (optional) - Enterprises PN: G301041 (6510) / NGK LTR7IX-11 Iridium 6510

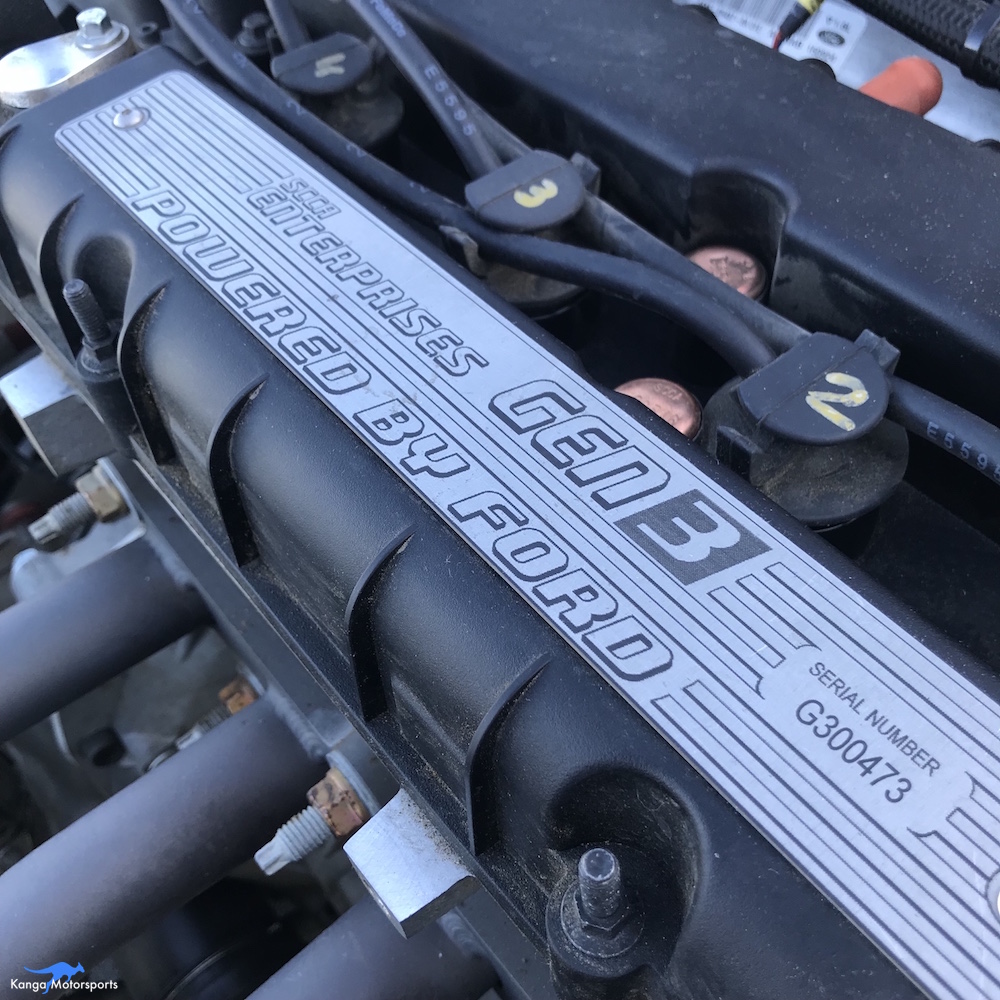

Compression Testing the SRF Gen3 Engine

The spark plugs and ignition wires are easily accessed on the Spec Racer Ford Gen3 since they are at the top of the motor. On the older Gen2 motor the process is the same but you will need to remove alternator to access spark plug #1.

While the plug wires are labelled and the ignition coil also has indicators molded into the plastic they can be hard to read. I use a paint pen to make larger straightforward labels when working trackside.

The compression test can be done either hot or cold. A hot compression test is done with the engine warm to ensure all the parts are up to temp and the clearances are as expected. If you suspect damage you might just want to perform a cold test instead of letting the motor sit and run to warm up.

Remove all the ignition wires from the motor you do not want any spark when running the starter. It is also a good idea to disconnect the fuel pump relay to prevent fuel being sprayed into the cylinders.

Remove the spark plug from the port using a spark plug socket, ratchet and extension to access and untighten. A magnetic spark plug socket or pick up tool can be hand for lifting the plug out of the hole.

It is a good idea to inspect the electrode and condition of the spark plug as it provides a visual health indicator of the combustion occuring in the cylinder. The electrode should be relatively clean without oil and black build up and have a smooth shape without chunks or pieces missing. You can also check the gap and inspect the body for cracks or damage to the insulation material. Here you see a relatively good condition spark plug.

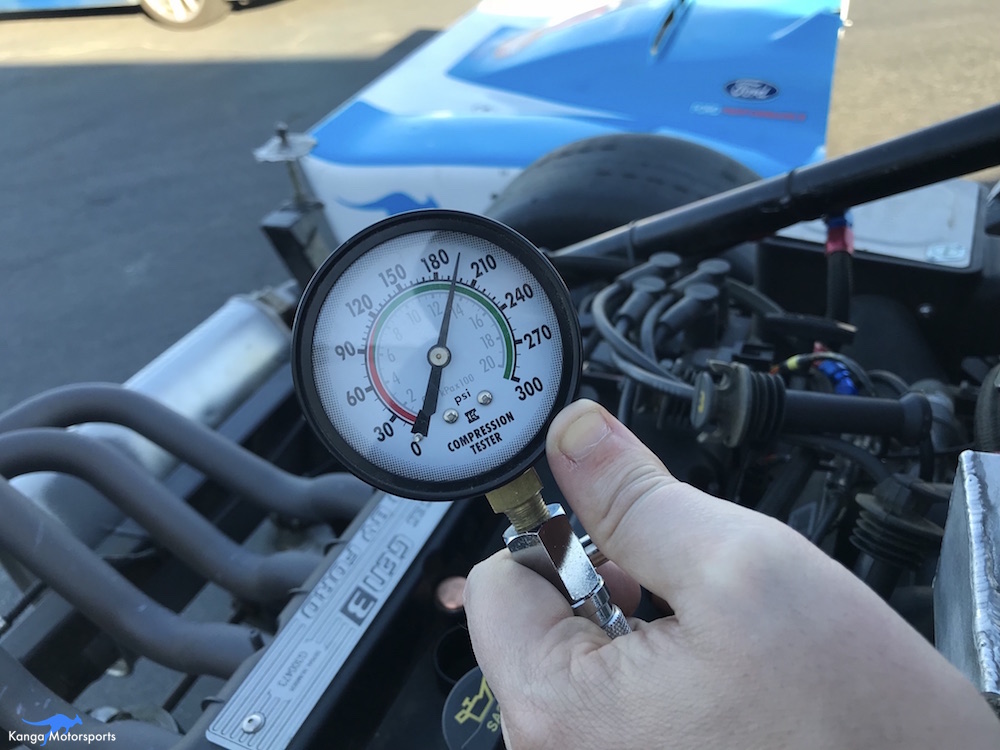

With the spark plug removed you can now screw in the compression gauge. Be careful not to cross thread and ensure it smoothly engages with little effort.

Hand tighten the gauge into place. Do NOT use tools or over tighten. Then position the plug where you can still see it while engaging the starter motor.

Turn on the Master switch. Bump the starter motor button 4-5 times. You should see pressure building in the cylinder with each turn. It should peak at a value of 180 to 200psi depending on your gauge. Here I was consistently getting numbers of 195psi plus or minus a few psi on a cold motor.

Turn off the Master Switch. Bleed the cylinder pressure with the relief valve and unscrew the compression test gauge.

A pro tip to reinstall the spark plug into the port. Pop a short piece of -6AN, 3/8th inch or 9.5mm fuel hose over the top electrode and porcelain insulator. This will give the extra length needed to reach the port and get the spark plug threads started by hand.

Tighten the spark plug into place by hand being very careful not to cross thread it into the soft aluminum threads of the cylinder head.

Continue down the rest of the cylinder for each spark plug and repeat the compression test for each cylinder. Remove the spark plug, inspect, install the gauge, bump the starter motor, read the gauge, relieve pressure, remove the gauge and reinstall the spark plug.

You should get good (180-200 psi) numbers across all cylinders. If one cylinder is significantly lower or different from the others this might indicate a sealing issue. It could be caused by piston rings, valves or gaskets. A leak down test can help diagnose the guilty party.

Once you have complete your test of all cylinders. Make sure all spark plugs are back in place. Tighten with the socket, ratchet and extension. Do NOT over tighten and go crazy here. Then reinstall the ignition coil wires in the correct order 4-3-2-1 from left to right if behind the car facing the front. Push down firmly and make sure each plug wire is seated snug.

If the engine is healthy you are now ready for another on track session. Go beat those lap records!

When replacing or refilling the Spec Racer Ford coolant system you need to make sure the all the air is bled out of the system before heading out on track.